INDUSTRY NEWS

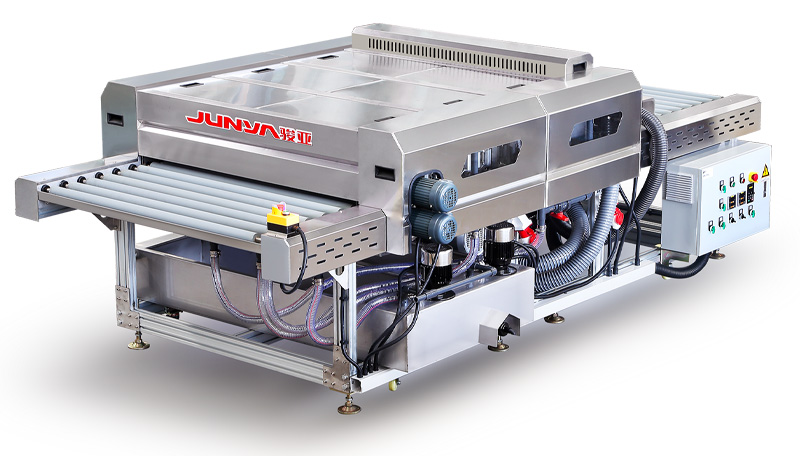

An Amazing Gadget - Insulating Glass Washer

The operating principle of the insulating glass washing machine is based on the perfect combination of automated machinery and hydrodynamic technology, with the significant advantage of significantly increasing productivity and ensuring product quality. The core principle of this machine is the use of high-pressure water jets and brushing technology to remove dirt and dust from the glass surface. Specifically, the glass is transported through a sophisticated drive system to different treatment locations, where it is sprayed, brushed, rinsed and air-dried in sequence.

Firstly, the water spraying stage: using the high pressure generated by the water pump, fresh water is pumped out of the tank and sprayed onto the glass surface. This step effectively removes most of the loose dirt and dust, laying the foundation for subsequent deep cleaning.

Next, the brushing stage: after spraying the water, the machine intelligently selects whether to use a soft-bristled brush or a hard brush for further brushing as needed. This step is specifically designed to target those more stubborn stains, ensuring that every area is thoroughly cleaned.

Next, the water rinsing stage: the scrubbed glass is then rinsed with plenty of water to ensure that all dirt and cleaning agents are removed. This process not only ensures the cleanliness of the glass, but also prepares it for final drying.

Then, the pure water rinse stage: Some high-end glass cleaners will use deionised or pure water for the final rinse to avoid water spots and ensure the ultimate cleanliness of the glass. This step is key to ensuring the quality of the product and is one of the ingenious ideas in the design of the machine.

Immediately after, the air-drying stage: after cleaning, the glass surface is blown dry using cold or hot air. This step avoids water stains and spots and ensures that the glass is dry and clean so that the product presents the best appearance quality.

Finally, the electric control system stage: the entire cleaning process is controlled by an advanced electric control system, which ensures that each step can be executed precisely. This not only ensures the cleaning effect, but also ensures the operation safety of the equipment, reflecting the application of modern technology.

The advantages of insulating glass washing machine are mainly reflected in the following aspects:

1. Enhance production efficiency: the automated process significantly improves work efficiency and reduces the need for labour, especially in mass production.

2. Ensure product quality: through precise control of each washing and drying process, it ensures that each piece of glass can achieve a high standard of cleaning quality and reduces the production of defective products.

3. Saving resources: Compared with manual cleaning, the machine can use water and cleaning agents more efficiently, reducing production costs.

4. Improve the working environment: automated equipment reduces the opportunity for workers to come into direct contact with detergents and water sources, improving the working environment and conforming to the human-centred principles of modern industrial production.

5. Strong adaptability: able to adapt to different thicknesses and sizes of glass cleaning, high flexibility, can be adjusted and customised according to actual needs.

In short, the introduction of insulating glass washing machine not only optimises the production process, reduces the cost, but also improves the quality of the product, which is an indispensable part of the modern glass manufacturing industry.